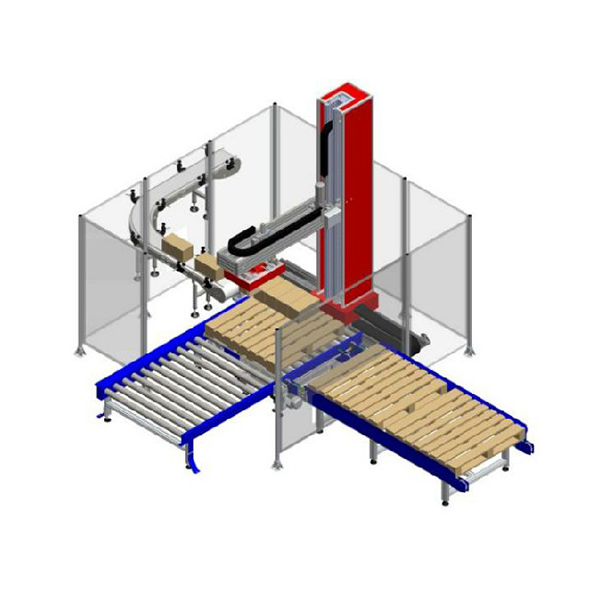

CR-4505_4507 film stretch wrap machine

Customized film stretch wrap machine for whole packaging line

Automatic Rotating turntable/Rotary arm wrapping machines for integrating complex one production lines or stand-alone wrapping machines

CR-4505Automatic Rotating turntable wrapping machines for integrating complex one production lines or stand-alone wrapping machines

1.Fully automatic unmanned operation:The automatic Rotating turntable wrapping do not need the intervention of the operator either in the hooking stage of the film or in the final expulsion stage, the pallet in fact reaches the machinery through a roller which places it correctly at the centre of the platform; here the machine proceeds in wrapping it according to the program set previously by the operator, and once the process is completed, it is expelled.

2.Integrating complex one production lines: Rotating turntable wrapping machines online is a packaging machine suitable for assembly line operation It is very suitable for the needs of automatic packaging in modern enterprises It plays a very positive role in improving packaging efficiency, reducing labor intensity and making effective use of human resources

3.Application fields: these products have been widely used in the packaging lines of chemical industry, electronics, food, beverage, papermaking and other industries; PLC programmable control, automatic film breaking, winding layers, top crossing height and reinforcement layers can be directly set on the panel

4.Operation steps: just press the automatic operation button to complete the whole packaging process, and automatically and manually switch at any time. Selected electrical control components, high reliability. Photoelectric switch to automatically sense the height of goods.

Technical parameters

|

Model |

CR-4505 |

|

Power |

220V 50HZ 2.4KW |

|

Max packaging size |

1200*1200*1800mm |

|

Rotating turntable diameter |

2000mm |

|

Rotating turntable bearing |

1500KG |

|

Rotating turntable speed |

0-10 r/m |

|

Dimensions |

2700*1850*2500mm |

|

weight |

1200KG |

CR-4507Automatic Rotary arm wrapping machines for integrating complex one production lines or stand-alone wrapping machines(Loose, light,bulky packaging)

1. Features: this type of rocker arm winding machine is mainly an on-line machine, in which the goods rotate on the conveying line, while the rocker arm machine does not rotate the goods, and the winding film rotates around the goods, so that the goods will not collapse due to the centrifugal force generated by rotation.

2. Scope of application: applicable to large and loose goods packaging and effective use of human resources. Unmanned operation. Automatic feeding, film feeding, winding, film cutting, film pasting, discharging, warehousing, etc.

3. Easy operation: PLC programmable controller and man-machine dialogue touch screen are adopted. Automatic warning, automatic fault alarm, etc. Simple operation and durability. Robust fuselage design, reasonable and ingenious Mechatronics combination.

| Model | CR-4507 |

| Power | 380V 50/60HZ 3KW |

| Max packaging L | L500-1300 |

| Max packaging W | W500-1200 |

| Max packaging H | H1800mm |

| Rotary speed | 0-15R/M |

| Bearing | 950kg |

| Dimensions | 3350* 2200*3800mm |